The fabrication will be carried out by skilled craftsmen in essentially the same tried and true method as it was decades before.

Understandably, the conservation process for this piece was lengthy considering the musty and damp environment it sat in for decades. When All Saints Episcopal Church changed locations to accommodate its suburban audience, they didn’t have enough room to display this window along with others. As a result of this, it was left behind in the first location’s basement. Years later when the first location was bought and the plan was to have it demolished, the windows(Christ Resurrection and Christ Blessing the Children) had to be relocated. Seeing as there was no space to display these windows they were returned to storage in the new building’s basement. Decades later, as the windows in the current building needed some conservation work, Scott Taylor of E.S. Taylor Studio was hired for the job. He was told that there was a possibility of more windows being in storage and this was how the Christ Resurrection and Christ Blessing the Children windows were rediscovered.

Lamb after restoration with epoxy

Lamb before epoxy gluing with torn edges

The unfortunate conditions in which the window was stored, high humidity, moisture, dirt, debris, insect activity, caused damage to the window. Taylor also discovered that the window was a plated window. This changed the scope of work considerably due to the amount of layers Taylor now had to remove and assess. Unfortunately, there were a number of missing pieces thought to have been left behind at the original church. These would have had the possibility of matching the visible indentations, but they could not be found, and ultimately had to be replaced. Not only were there missing pieces but there were also broken pieces. In order to repair this, Taylor had to remove the glass from the lead to be cleaned of thick resin and then realigned. In order to glue the pieces back, conservators used a special type of glue or adhesive called HXTAL NYL-1 which is an epoxy. In some cases the epoxy had to be tinted to match the surrounding glass.

Not only were there missing or broken pieces, there were also specific portions of the window undergoing deterioration, or crizziling. This was caused by high levels of alkali and low levels of lime. Due to this imbalance over time, changes in moisture levels can cause runs in the glass and then breaks. The biggest problem with runs¹ forming is that it detracts from the beauty of the piece by not letting as much light through. Conservators had to consolidate, or strengthen the glass with an expoxy, even though this was irreversible it was the only solution to prevent glass from continuing to degrade and break. Conservators noticed that this kind of damage can cause the glass to crumble right out of the lead. When crizzled glass begins to form, it can be stopped, but it cannot be reversed. Although the damages were significant, conservator Scott Taylor was able to ‘resurrect’ this window.

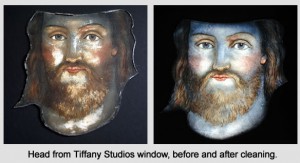

(All Slideshow Images) VMFA Art Installation: Tiffany Windows 2008.48a-c, “The Resurrections” – Cochrane Lounge 5/19/2010. Photo: Travis Fullerton Copyright Virginia Museum of Fine Arts

Tiffany Window’s Curator Interview

To read the full interview click here!

Exploring Tiffany Windows.

Ready to learn more? Following the links below to explore!